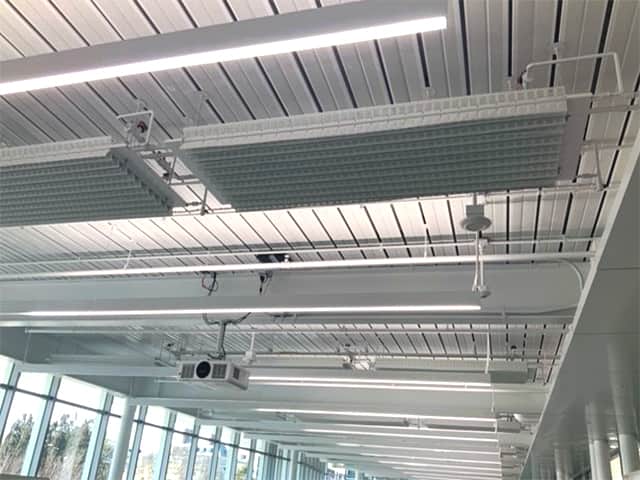

Frenger Systems provide X-Wing® radiant passive chilled beam to UIUC Siebel Centre

Frenger are proud to have supplied our 'Exposed' X-Wing® Radiant Passive Chilled Beams to the recently completed new 60,000 square foot UIUC Siebel Centre in Champaign, Illinois.

This new cross-disciplinary academic building at the University of Illinois at Urbana-Champaign provides students with a facility designed to harness and support a collaborative approach to problem solving – one that combines design thinking, experimental, prototyping and making in an open, flexible and collaborative cross-disciplinary environment.

Our X-Wing®'s 40% Radiant quotient not only helps to provide effective energy-efficient cooling to the indoor space but also delivers an excellent indoor climate environment which is essential for student wellbeing and performance.

This is achieved by providing cooling by both "Radiation" and convection. The products radiant proportion creates no air movement, the cold surfaces of the beam (4 radiant wings per waterway) absorb heat radiation from the building occupants and the warmer surrounding surfaces. X-Wing's® radiant quotient is approximately 40% of the total cooling effect (the other 60% of cooling being generated by the convective cooling). The ability of X-Wing® to cool by radiant absorption means that, when compared to other passive chilled beam types, Frenger's X-Wing® can deliver up to circa 40% more cooling without any additional air movement, hence approximately 40% less risk of any draft.

In addition to the above radiant cooling process, the only air movement comes from the convective proportion. As cold water passes through the chilled beam the warm room air is cooled against the beam's cooler surfaces. This cooled air, which is heavier due to its higher density, then percolates through the punched louvers in the radiant wings. In this way, the air is circulated within the room, with warm air from the room being continually replaced by cooled air whilst still maintaining high thermal comfort levels to the building occupants.

Our X-Wing® product is constructed from copper and aluminium and is 100 percent recyclable. The copper coil is produced by Frenger's in house fully automated bespoke "state of the art" full CNC serpentine bending machine. This produces seamless sinusoidal copper coils (without any joints in the product, hence no risk of water leakage). The aluminium radiant "wings" are produced in house by bespoke power press and roll forming machines, all of which are then assembled by Frenger's fully automated CNC controlled machine which mechanically bonds the "radiant wings" to be in metal-to-metal contact with the seamless copper waterways.

For more information on Frenger's cooling & heating solutions, or if you require design support selecting our products then please contact us on 646-571-2151 or sales@frenger.co.uk